Additionally, the precision CNC turning system crafts intricate details and shapes on account of workpiece rotation rather than cutting tools. The stationery tool can transfer across the workpiece for any exact materials elimination course of action.

Two major things in selecting over a reliable precision machining associate for your factors & solutions are technical capabilities and practical experience inside the associated industry.

CNC plasma cutter can be a CNC cutting machine, comparable to CNC milling machines in The reality that they share precisely the same purpose, that may be to remove material to make the desired Lower.

The choice in the machine is dependent on the shape in the workpiece, the type of fabric, the accuracy required, and the machining operation to generally be executed.

The series inside the horizontal machining center section of DMG MORI variety a whole portfolio for horizontal CNC machining. With the highly stable NHX sequence for max precision on the DMU/DMC H monoBLOCK products for reliable universal machining procedures, the high-tech software presents full tailor-created solutions For each require: from universal milling of fixing portions to highly automated collection production of motor elements during the automotive industry.

CNC Lathes: CNC lathes are perfect for developing cylindrical parts, as their workpiece rotates even though their cutting tool remains stationary. This type of machine is commonly used for making parts for instance shafts and pipes.

The selection of machine relies on the type of occupation, the accuracy needed task spending plan, and the time available to full the job.

CNC Machining continues to be an priceless useful resource in right now’s highly competitive manufacturing setting. It permits corporations to generate intricate parts with greater accuracy, regularity, and efficiency.

CNC Waterjet cutters, since the identify implies, use high-pressure jets of water to cut by means of elements. Ordinarily CNC H2o-jet Cutting is opted for when the material for being worked on is delicate to temperature and could melt at high temperatures, like plastic and aluminum.

Unlock entry to your Share Hub and a number of other capabilities and services. With a central DMG MORI Account, You may use all services across the clock from everywhere and with any device.

The Okuma LU-300M is a part with the LU series of CNC lathes known for innovation within the machining industry. Over the years, it's got expanded its abilities and preserved a name for high quality.

This price features shipping and delivery cost, export and import obligations, insurance coverage, and any other expenses incurred all through delivery to some location in France agreed with you for a purchaser. No other mandatory expenditures might be included for the delivery of a Haas CNC Products.

The CNC milling machine consists of a rotating cutting tool, which often can go along multi-axis linear and rotational motions with a liner feed of the workpiece. The spindle can rotate at high speed( as many as 2400 rpm) without compromising precision and excellent, as low as +/-0.

You would absolutely need to use IPR for your feed. Any threading cycle on an Okuma quickly ignores all feedrate overrides, feedhold, and so on in the course of the period with the cycle so that you can't mistakenly hit a button or twist a knob and lead to a wreck. By making use of IPR the feed is decided within the control, so that you undoubtedly don't desire to substitute your individual calculated feedrate which might then rely upon the programmed spindle speed becoming great. I have hardly ever tried using it, but I do not think the control would even settle for an IPM feedrate for tapping. Here's why: When the faucet reaches full depth and also the spindle stops, the quit is not instantaneous. In the course of the next or so that the spindle decelerates, the feed in IPR stays coordinated and decelerates too. IPR feed assures that no spindle rotation = no Explore feed. When the spindle reverses and accelerates to speed, the feed accelerates together with it. Should the feed is about at .0625 ipr, the control isn't going to care if it takes two seconds to the spindle to turn 1 rev, or if it takes it one/10 next.

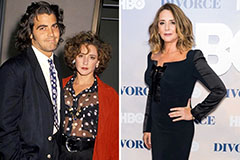

Talia Balsam Then & Now!

Talia Balsam Then & Now! Monica Lewinsky Then & Now!

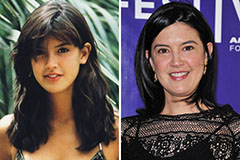

Monica Lewinsky Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!